Engineered for Your Success

Based on 20 Years

of Expertise

With two decades of specialized crane manufacturing experience, we master core technologies to ensure every unit is safe and reliable, empowering projects worldwide.

Yuefeng

Company Profile

Shandong Yuefeng Hoisting Machinery Co., Ltd. is located at Beishou, Quantou Village, Xizhangzhuang, Xintai City, Shandong Province. The company is a professional manufacturer of hoisting machinery equipment approved by the National Market Regulatory Administration. Established in March 2007, the company covers an area of 110 mu, with a registered capital of 128.8 million yuan. By the end of 2017, its total assets reached 250 million yuan. The company is equipped with over 120 production and testing facilities and employs more than 200 staff, including 60 mid-to-senior level technical professionals and management personnel.

Crane supply industry

The company manufactures bridge cranes, gantry cranes, and light-duty cranes, serving multiple industries and selling to more than 20 provinces and cities.

Customized high-efficiency cranes

A professional team customizes cranes, optimizes designs to improve efficiency, reduces costs, and adapts to different needs.

Product Center

Professional lifting equipment, the best choice

BRIDGE CRANES

APPLICATIONS

FEATURES

GANTRY CRANES

APPLICATIONS

FEATURES

BRIDGE CRANES

APPLICATIONS

FEATURES

GANTRY CRANES

APPLICATIONS

FEATURES

FACTORY TOUR

On-site visit and quality traceability

Shandong Yuefeng Hoisting Machinery Co., Ltd.

Total Assets

(As of the end of 2017) 250 million RMB

Corporate Positioning

Beishou, Quantou Village, Xizhangzhuang Town, Xintai City, Shandong Province

Address

Lifting Machinery Manufacturer Approved by the State Administration for Market Regulation

PRODUCTION WORKSHOP

Main Products

Bridge cranes, gantry cranes, light lifting equipment

Service Industries

Hydropower, metallurgy, chemical, coal mining, and many other industries

Sales Area

More than 20 provinces, municipalities, and autonomous regions in China

PRODUCT INSPECTION

Factory Pass Rate

100%

Delivery Requirements

Delivery only after all items pass inspection

Inspection Process

All inspection items: Item-by-item inspection before production and shipment

Engineering Solution Discussions

Professional Team

In-house professional design team, customizing cranes to your needs

Optimized Design

Compact structure, greater lifting height within the same factory building

Cost Savings

Used in new factory buildings, allowing for reduced building height and lower costs

RAW MATERIALS WAREHOUSE

Steel Plate Processing

Stress relief using a leveling machine, shot blasting for rust removal

Main Structure

Materials: Q235-B or Q345B steel plates from well-known manufacturers

Cutting Process

Key plates of the main end beams are laser/plasma/CNC cut; the rest are formed in one step using a shearing machine.

PRODUCT SHIPPING

Industry Position

Nationally leading company in the industry

Development Accumulation

Years of accumulated production management experience

Team Capabilities

All staff members are highly professional, technically skilled, and managerially competent

Why Choose Us?

Strict control over the entire process

The product has undergone rigorous testing, is reliable and cost-effective, and is suitable for various working conditions.

High reliability

Rigorous Testing

Precision forging

Precision Manufacturing Process, Ingenious Production

A Comprehensive Overview of the Six-Step

Crane Production Process

01

Raw Materials

Rigorous screening of high-strength steel to meet heavy-duty requirements from the source.

02

Blanking

High-precision laser cutting ensures steel plates are accurately segmented to design specifications.

03

Assembly

Standardized assembly processes form core structures like main girders and end trucks.

04

Welding

Certified welders perform strict welding procedures to ensure critical joint strength and durability.

05

Spray Painting

Multi-layer anti-corrosion coating enhances long-term resistance in harsh environments.

06

Inspection

Each crane undergoes load testing and non-destructive inspection to guarantee 100% safety and reliability.

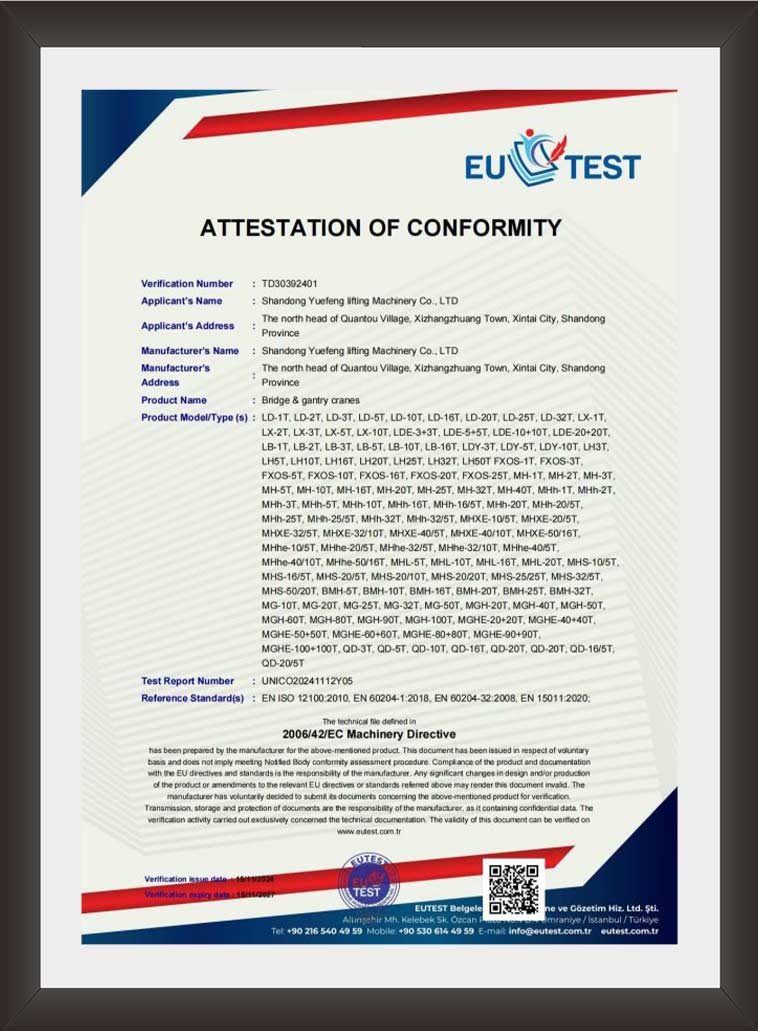

Authoritative Certification, Compliance Guarantee

Our certifications demonstrate

superior quality and reputation

- Industry-recognized certifications

- Strict compliance standards

- Comprehensive qualification matrix

Contact & Customization

Contact Us Now For Your

Customized Solution

All Types of Cranes

Double-girder / Single-girder / Gantry crane structure Full analysis

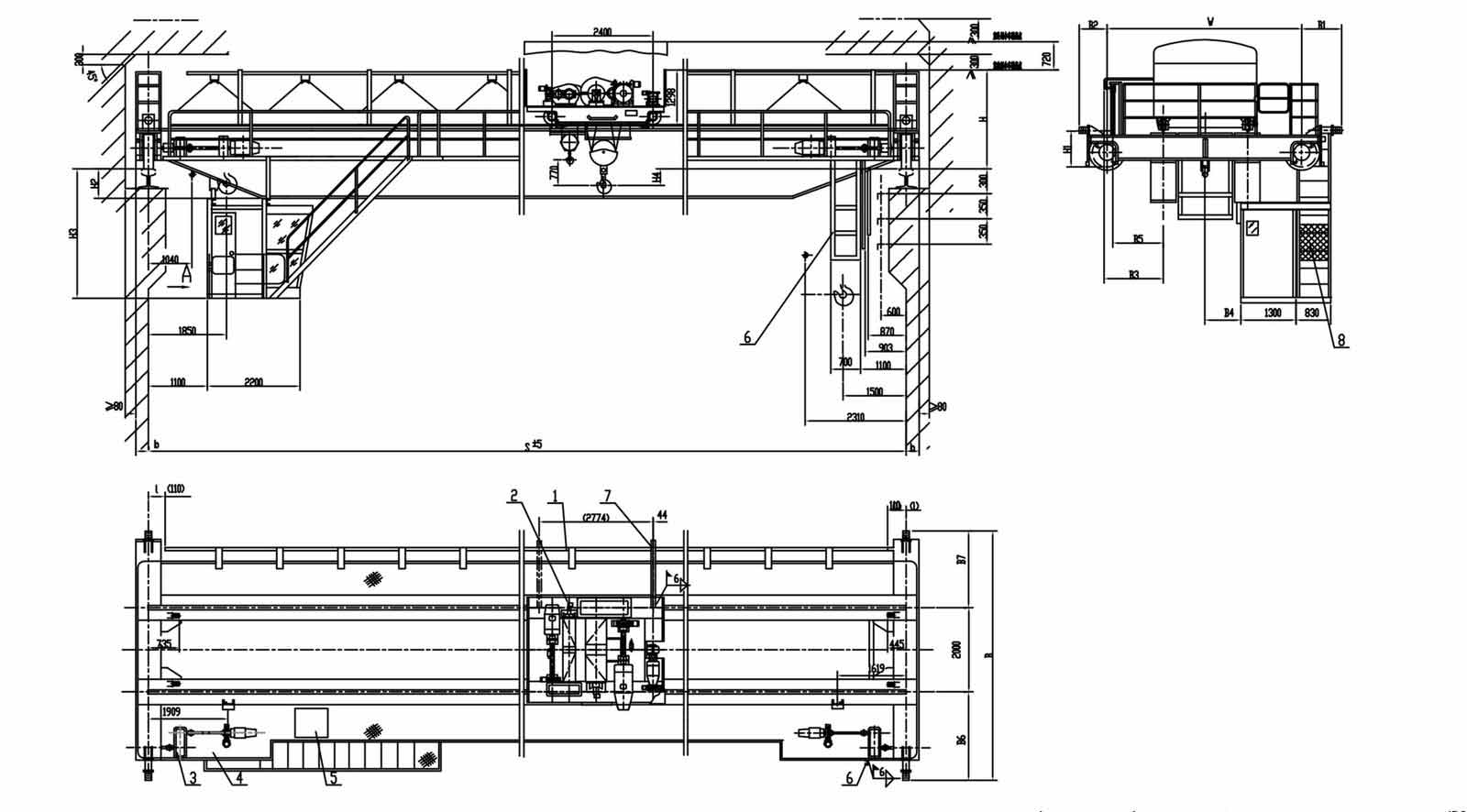

Double girder bridge crane

Heavy-duty workshop high-load lifting solution

The double main beam structure is suitable for handling large-tonnage indoor materials.

Structure:

High load-bearing capacity and excellent stability

Precision:

High operational accuracy

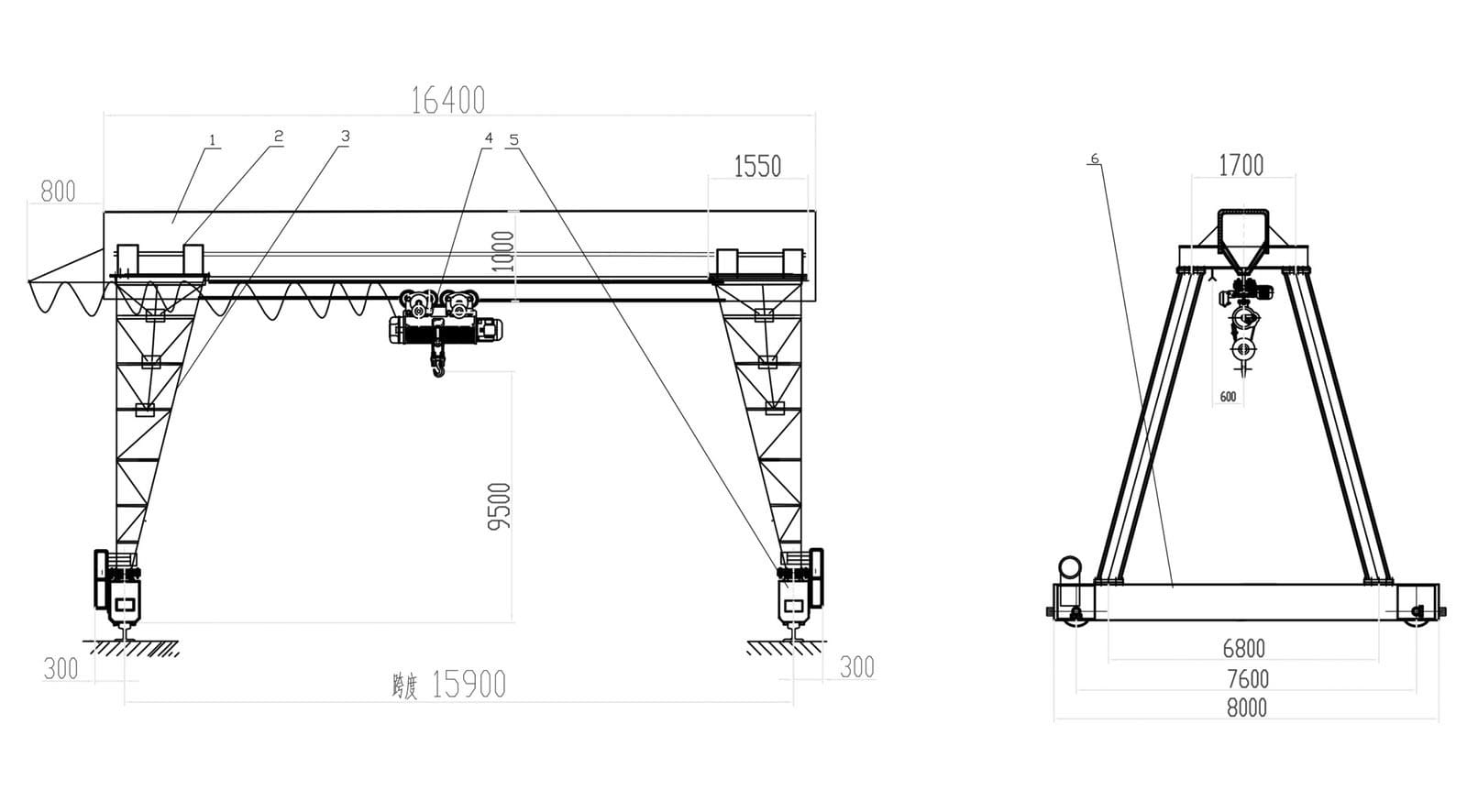

Truss gantry crane

Open-air, large-span bulk material handling expert

Truss legs + large-span main beam, suitable for hoisting in complex outdoor environments.

Structure:

Large span, stable and lightweight

Environment:

Strong outdoor adaptability

Efficiency:

High hoisting efficiency

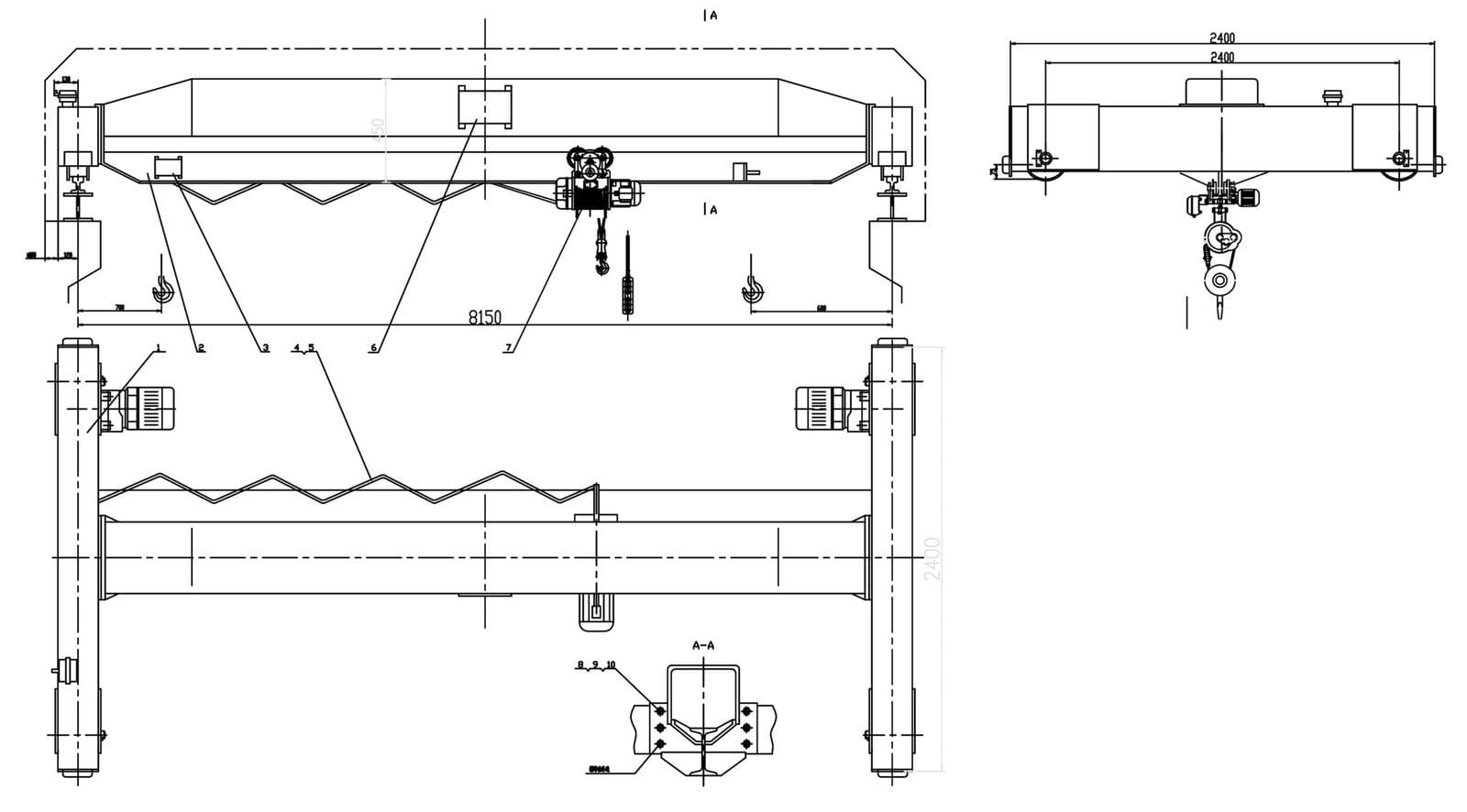

Single-girder bridge crane

Flexible lifting tool for small and medium-sized scenarios

The single main beam structure is compact and suitable for short-distance handling under medium to light loads.

Installation:

Simple installation, low maintenance

Efficiency:

Smooth operation, high efficiency over short distances

Economy:

Controllable costs

Yuefeng Crane News Matrix

Authoritative window for information on the crane industry

Beyond Material Handling: The Core Value of Cranes in Diversified…

When people think of cranes, they often imagine tower cranes on construction sites or busy…

The Weight of a Lifeline: Unveiling the Manufacturing Craft Behind…

A crane carries not only heavy loads but also the safety of personnel and the…

Smart, Green, Efficient: The Future Path of the Crane Machinery…

In the era of Industry 4.0 and “Made in China 2025,” the traditional crane machinery…

Yuefeng Crane News Matrix

Authoritative window for information on the crane industry

Beyond Material Handling: The Core Value of Cranes in Diversified…

When people think of cranes, they often imagine tower cranes on construction sites or busy…

The Weight of a Lifeline: Unveiling the Manufacturing Craft Behind…

A crane carries not only heavy loads but also the safety of personnel and the…

Smart, Green, Efficient: The Future Path of the Crane Machinery…

In the era of Industry 4.0 and “Made in China 2025,” the traditional crane machinery…